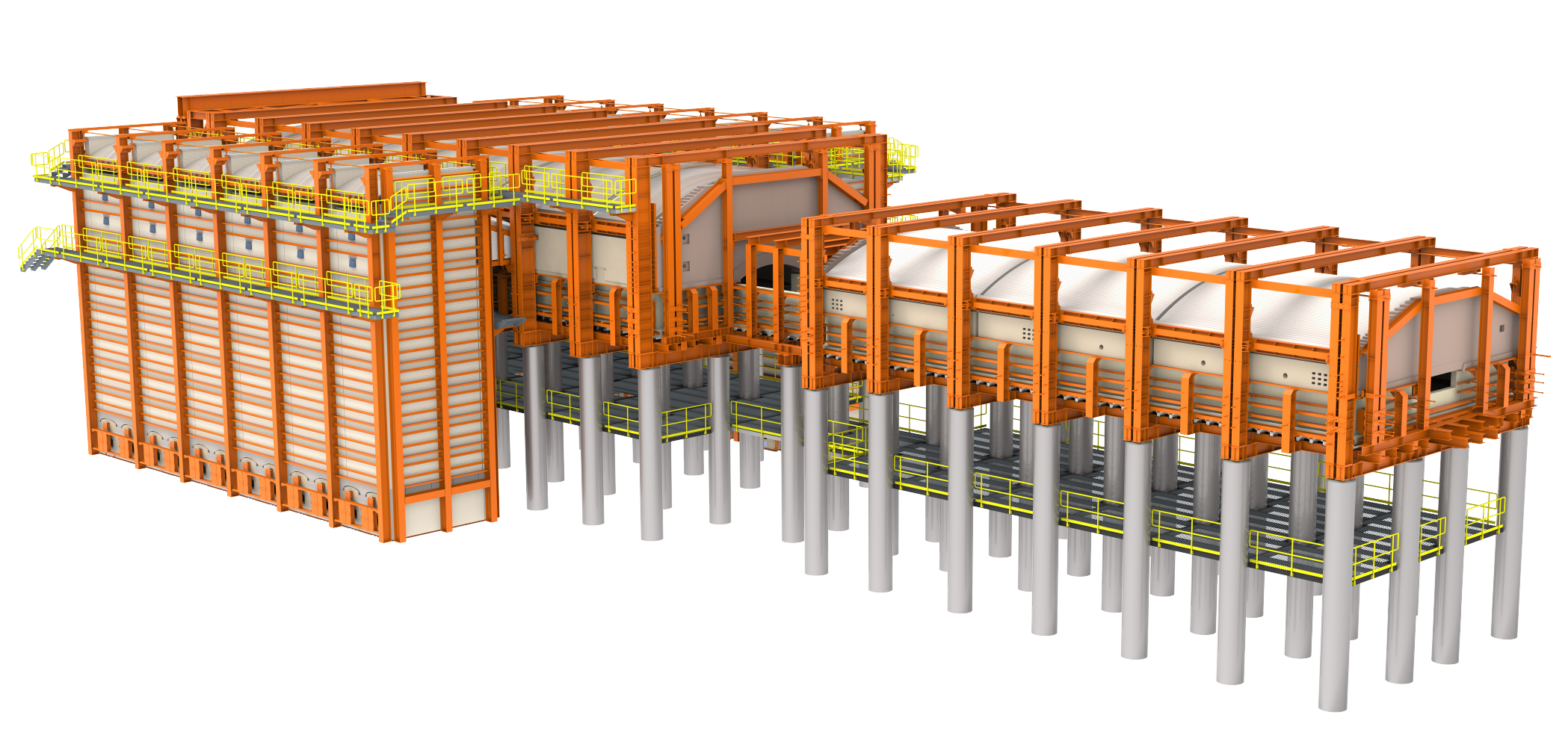

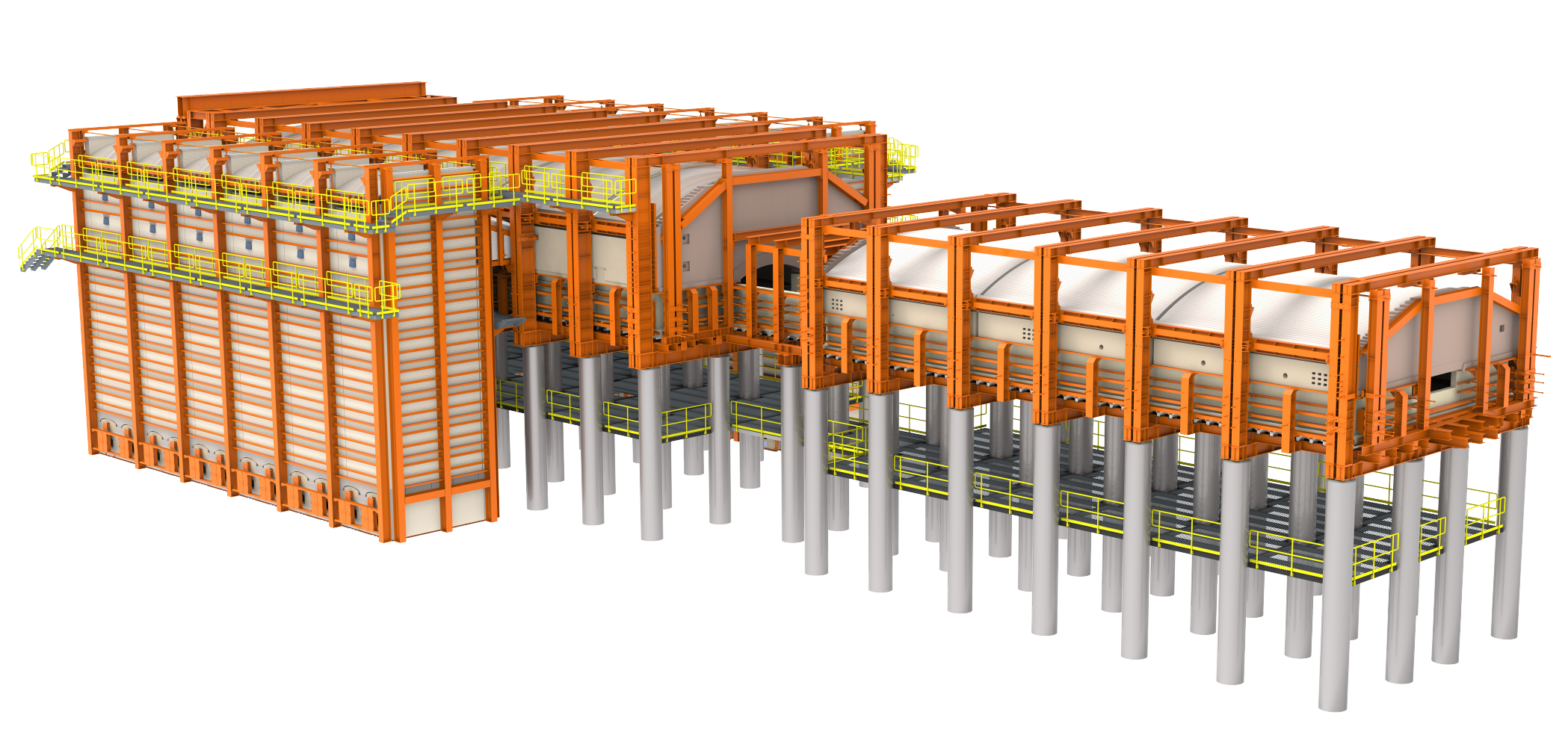

Stewart Engineers applies over 35 years of experience to design, develop, and deliver superior efficient melting furnace technology to the glass industry. EcoMelt® furnaces are regenerative, multi-port, cross-fired, and designed for long-life. Stewart can assist customers with specifying tonnage, fuel source, glass type, and automation level to suit their market needs. Stewart will design, develop, and install an EcoMelt® furnace to fit your needs.

| EcoMelt® Technical Capabilities | |

|---|---|

| Glass Composition | Soda Lime, Tinted, Low Iron, Borosilicate, Aluminosilicate |

| Tonnage | 50 - 1200 MTPD |

| Energy Efficiency | 1350 ± 10% KCAL/KG |

| Glass Level Precision | ± 0.15mm |

| Canal Temperature Precision | ± 0.7 C |

| Furnace Pressure Precision | ± 0.30 mmH2O |

Stewart's EcoMelt® furnace design is based on operational experience towards maximizing profit. Maximizing profit requires low defect counts, high pull per furnace CAPEX, and long life to minimize rebuild costs and rebuild lost production time.

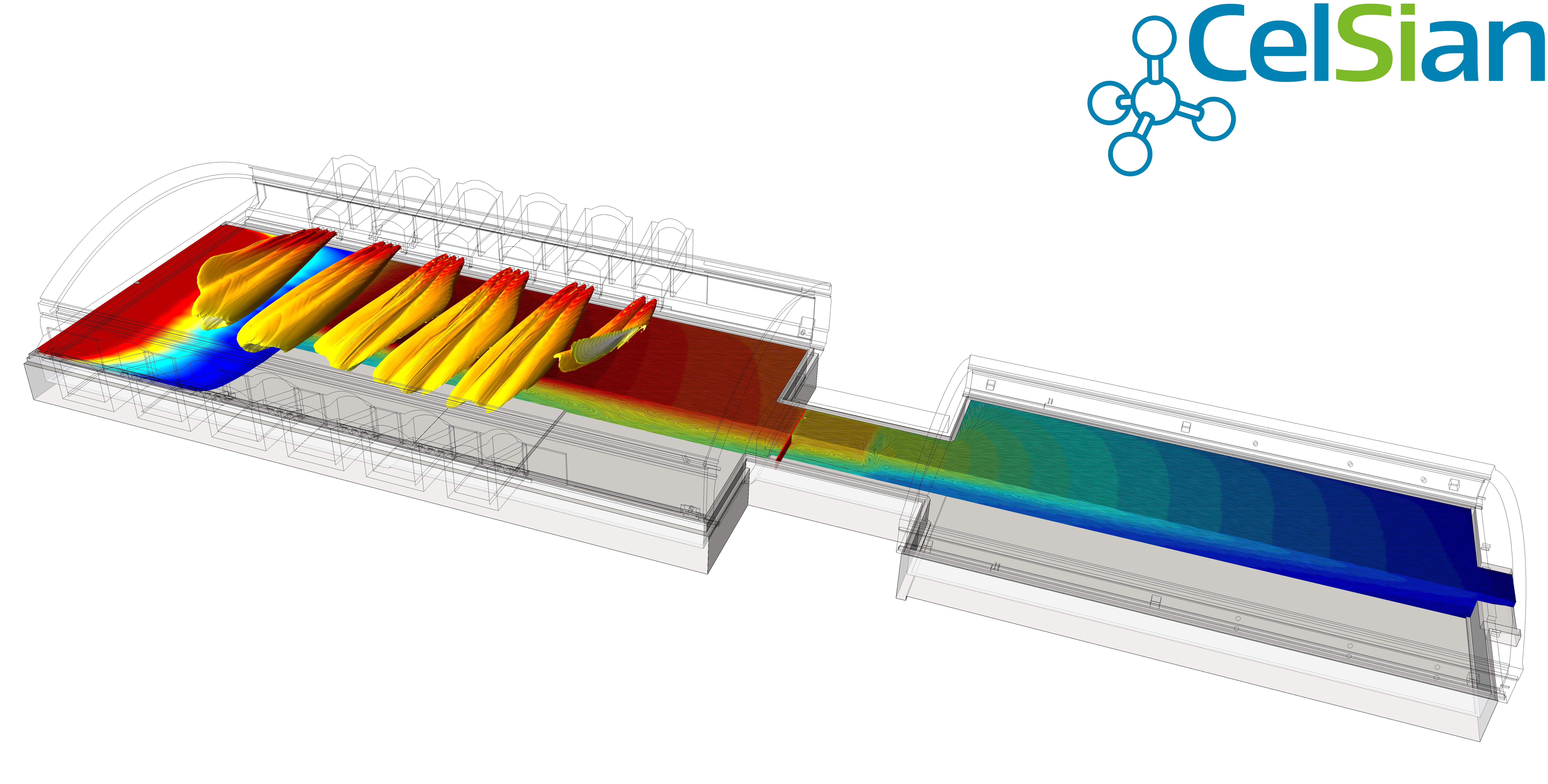

Below is a detailed computational fluid dynamics (CFD) simulation performed by CelSian.

EcoMelt® furnaces give independent float manufacturers access to the latest furnace technology. Two EcoMelt® based furnaces are in operation today in Italy with both producing premier quality float glass. The two furnaces combined have produced over 200,000 tons of ultra-clear glass. These two furnaces serve as the robust foundation for the EcoMelt® furnace.

Sangalli Group

Founded in the 1950s. First independent float glass producer in Italy.