AcuraCoat® Specialty Technology

Stewart Engineers can install the AcuraCoat® CVD hard coating system without process downtime in tin baths that were not originally designed for CVD.

- Installation in the bath and/or in the lehr

- Rapid on/off time to minimize glass loss

- Environmental control:

- We customize to your emissions regulations, baghouses and/or scrubbers

- Recovery and reuse of material for lower operating costs

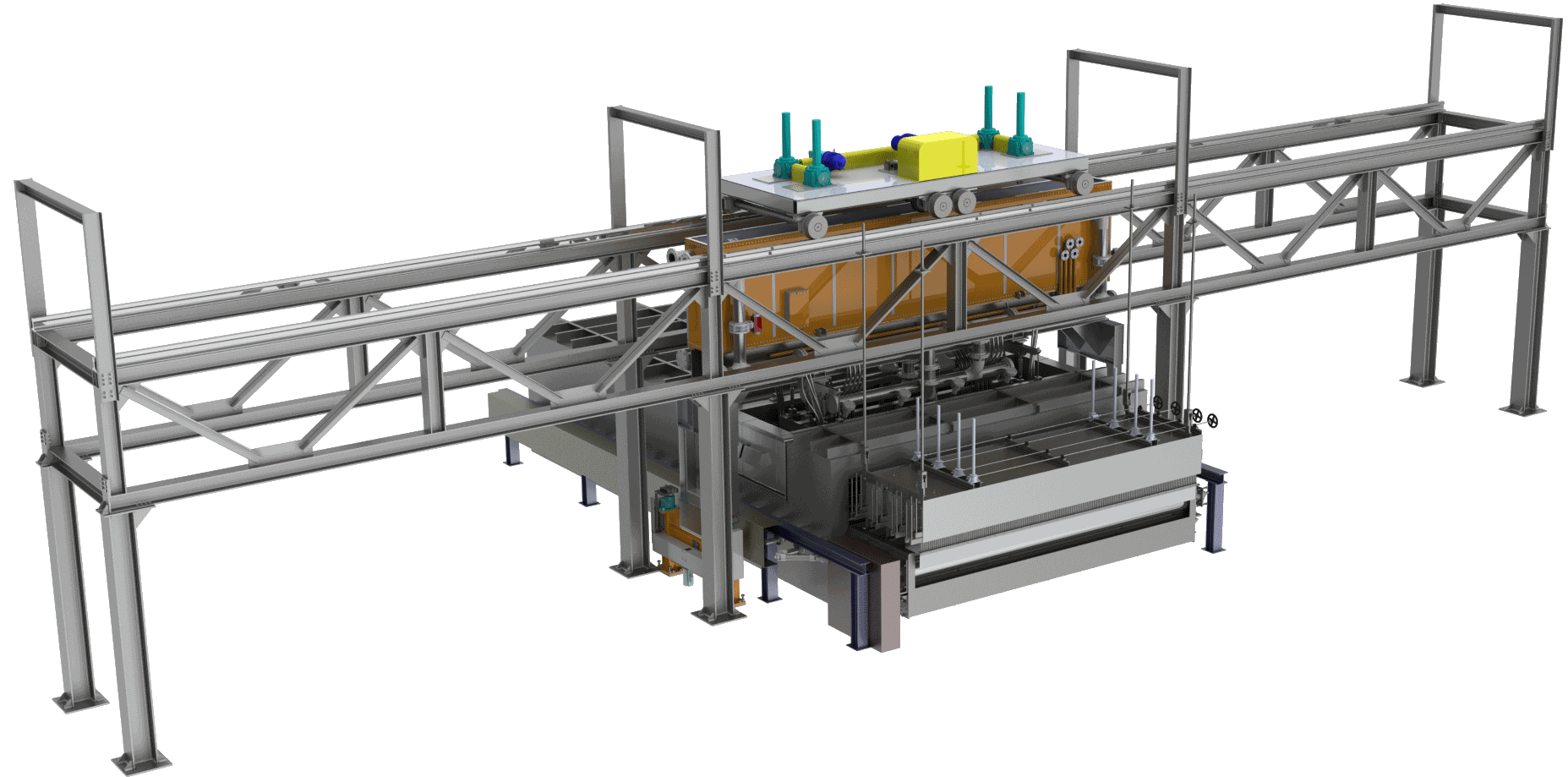

Customized Design Process

Stewart Engineers utilizes 3D CAD modeling of AcuraCoat® CVD Technology to achieve:

- Accelerated manufacturing and construction times

- Elimination of errors by identifying interference constraints before construction

- Automatically-generated bills of materials

- Parameterization and customization of the CVD coater design

Operational Expertise

Over thirty-years of CVD hard coat experience has equipped Stewart Engineers with the knowledge to develop:

- A selection of precursors for coatings

- Controlled delivery of precursors

- Methods of precise ribbon temperature control

- Uniform vapor flow and coating deposition

- Recognition and elimination of coating defects

- Integrated control systems to interface with process and emissions equipment

- Methods of remediating emissions and waste gas

- Process procedures, preventative maintenance schedules, training programs

- Laboratory quality control integration